Производитель измельчителей и дезинтеграторов для уничтожения данных

Главная / Quality Control

Quality Control

Quality Solutions

1、 Determine development projects, understand customer needs, including product quality requirements, equipment production efficiency requirements, and equipment working environment

2、 Analysis products

● Understand the production process, dimensional requirements and incoming materials of products

● Communicate with customers about the precautions in the production process and the technical parameters of the place where the equipment is used

3、 Proposed scheme

The engineering personnel discuss and analyze the equipment scheme, which includes: equipment schematic diagram (overall schematic diagram, local schematic diagram), introduction of each part of the mechanism, action description, and equipment technical parameters

4、 Scheme review

An audit team is formed by engineering personnel to audit the scheme, including equipment feasibility assessment, equipment cost assessment, equipment production efficiency assessment, and structural feasibility assessment of each part

5、 Scheme rectification

Rectify the problems discussed in the plan review.

6、 The customer determines the design scheme

The design scheme is handed over to the customer, who will finalize the scheme according to the requirements.

7、 Design and development

The Engineering Department shall arrange engineers to design the mechanism and make machine assembly drawings and parts drawings (parts shall be marked according to national standards)

Select the executive components and electric control accessories, and list the processing parts list, standard parts purchase requisition and operation instructions.

8、 Institutional review

The engineering personnel shall form an audit team to audit the designed drawings,

10、 Inspection and warehousing of processed parts and standard parts

11、 Machine assembly

12、 Machine commissioning

Sample Content

Generated for confidential destruction

Generated for confidential destruction

It is specialized in the production of confidential destruction equipment, and has many years of experience in the production of highly confidential destruction equipment. It provides a complete confidential destruction scheme for data centers, governments, banks, and the military.Destruction schemes and equipment of various disciplines

According to the different storage media, Sharp designs and produces a variety of destruction equipment and solutions, such as hard disk crusher, chip grinder, mobile phone crusher, high security paper shredder and other customized solutions.

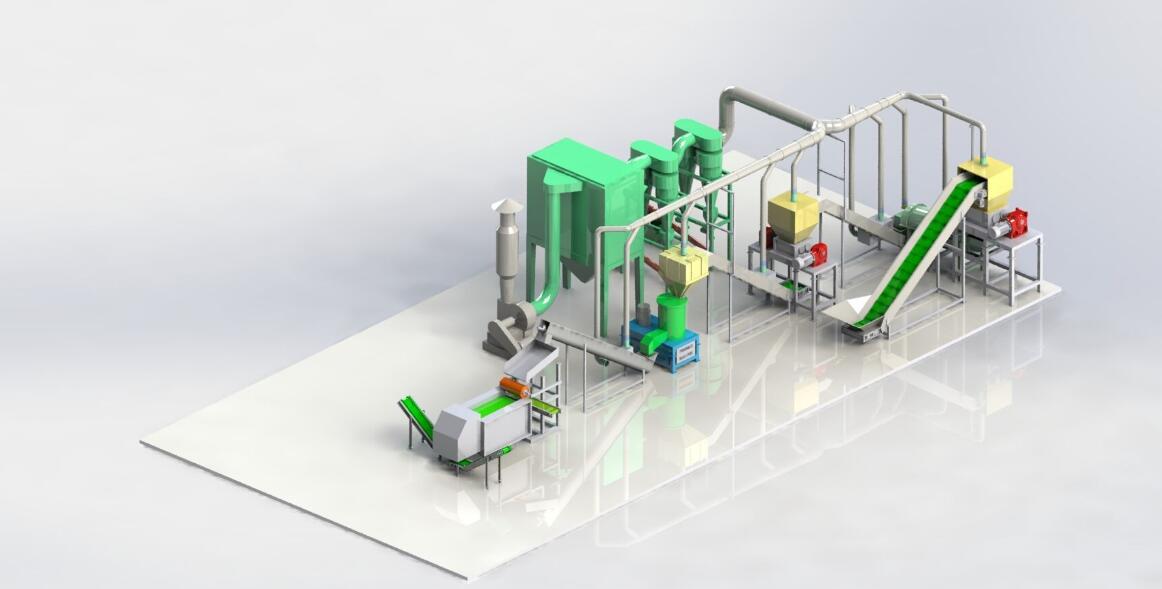

Modular design scheme to provide customers with a comprehensive integrated destruction system

According to the destruction requirements of customers, design the module selection scheme of equipment, such as the feeding system, crushing system, dust removal system, sorting system, crushing system, magnetic separation system, discharge system, briquetting system, etc., and design a mature and perfect destruction and recovery scheme for customers.

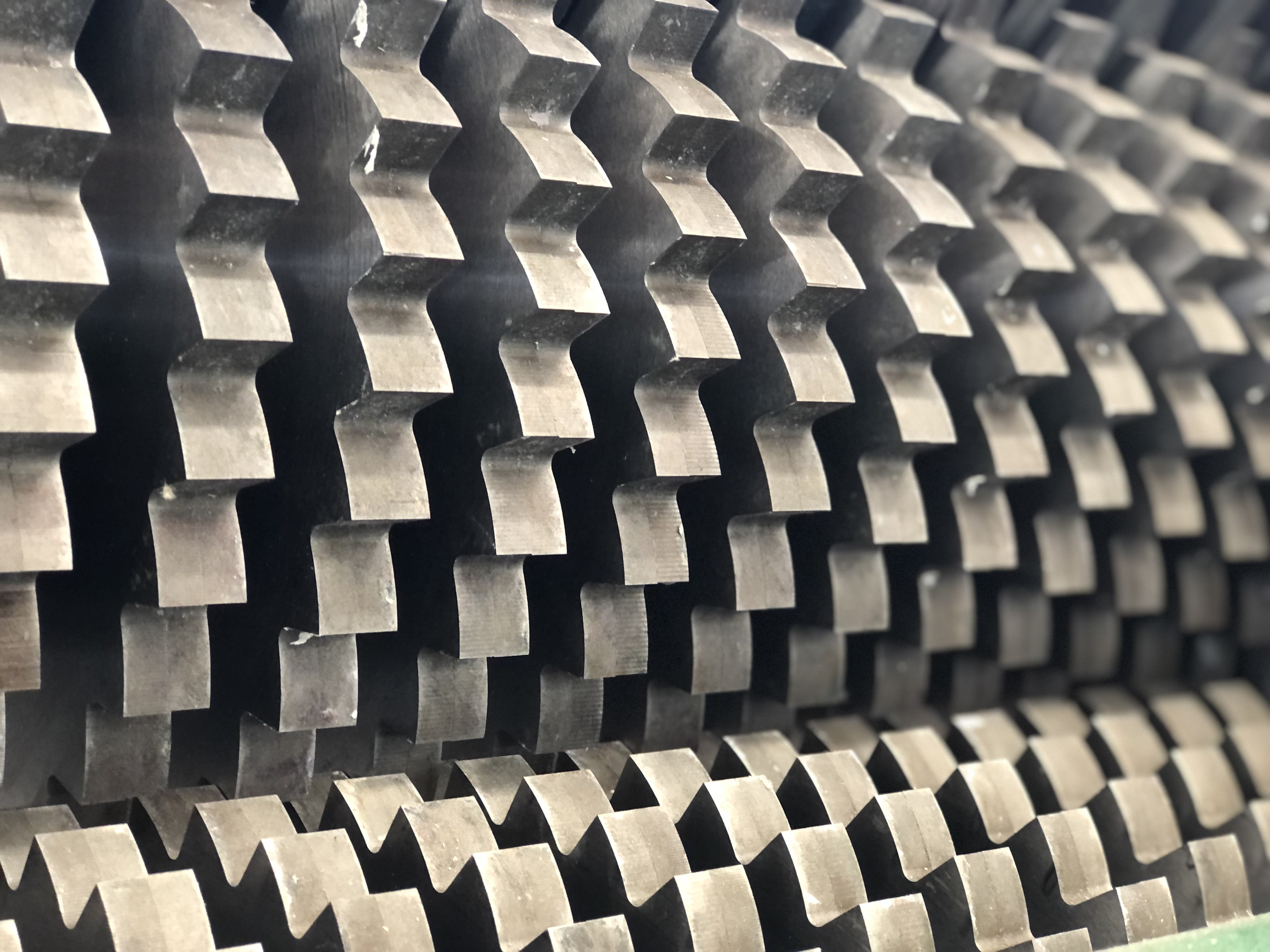

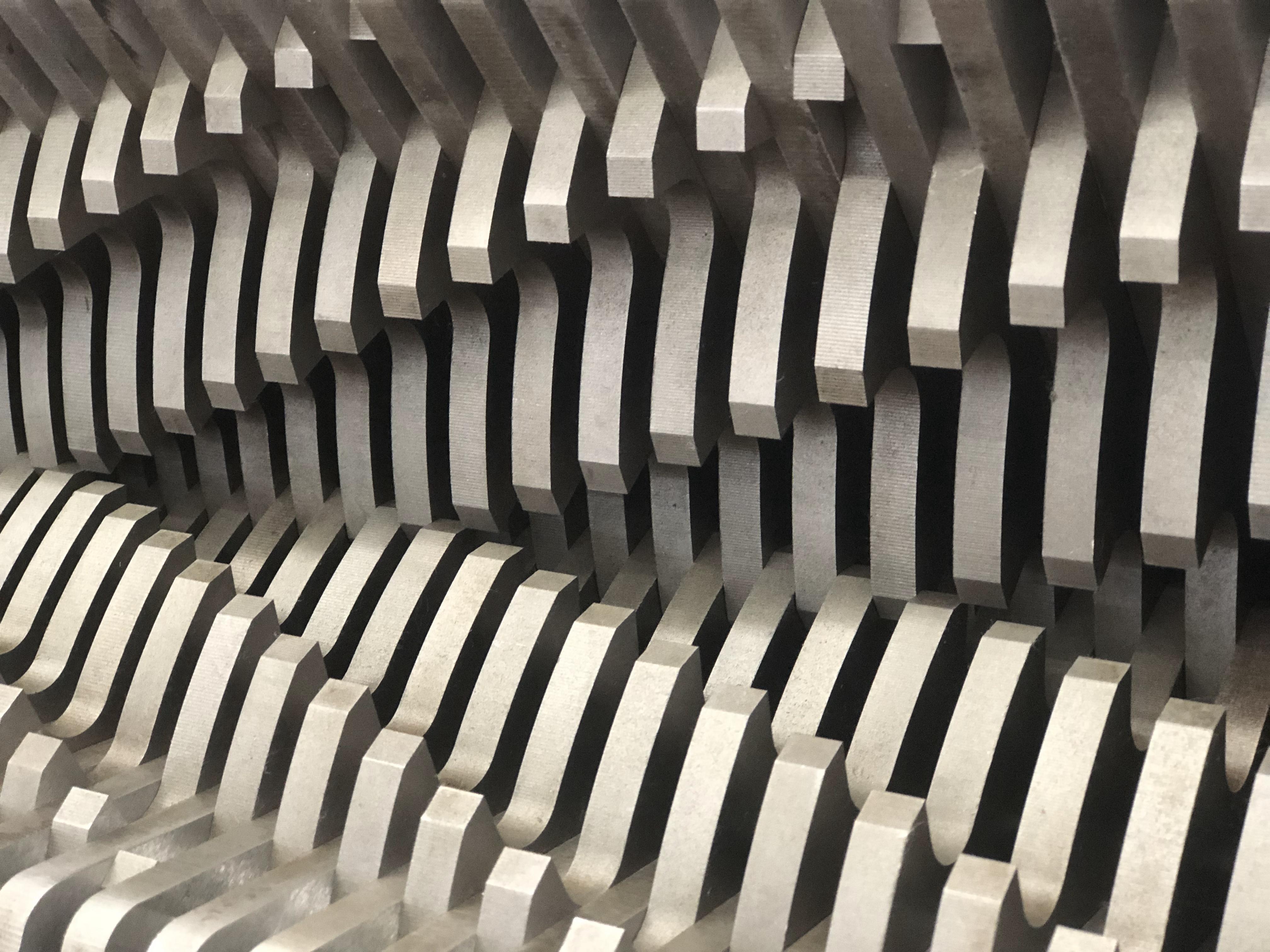

High strength shredding tool and shredding system

Most of our products are based on confidential destruction. The core of our products is to break the storage media, such as hard disks, chips, and paper, into the smallest size. Many materials contain a lot of metal, so the requirements for cutting tools are very high. Our cutting tools only have H13 grade materials. The cutting tools are designed according to different crushing materials. And can adapt to high-strength crushing

Planetary gear reduction system

The planetary gearbox is used to reduce the speed to transmit the crushing force of high torque, which can tear the machine metal more easily than other gearbox.

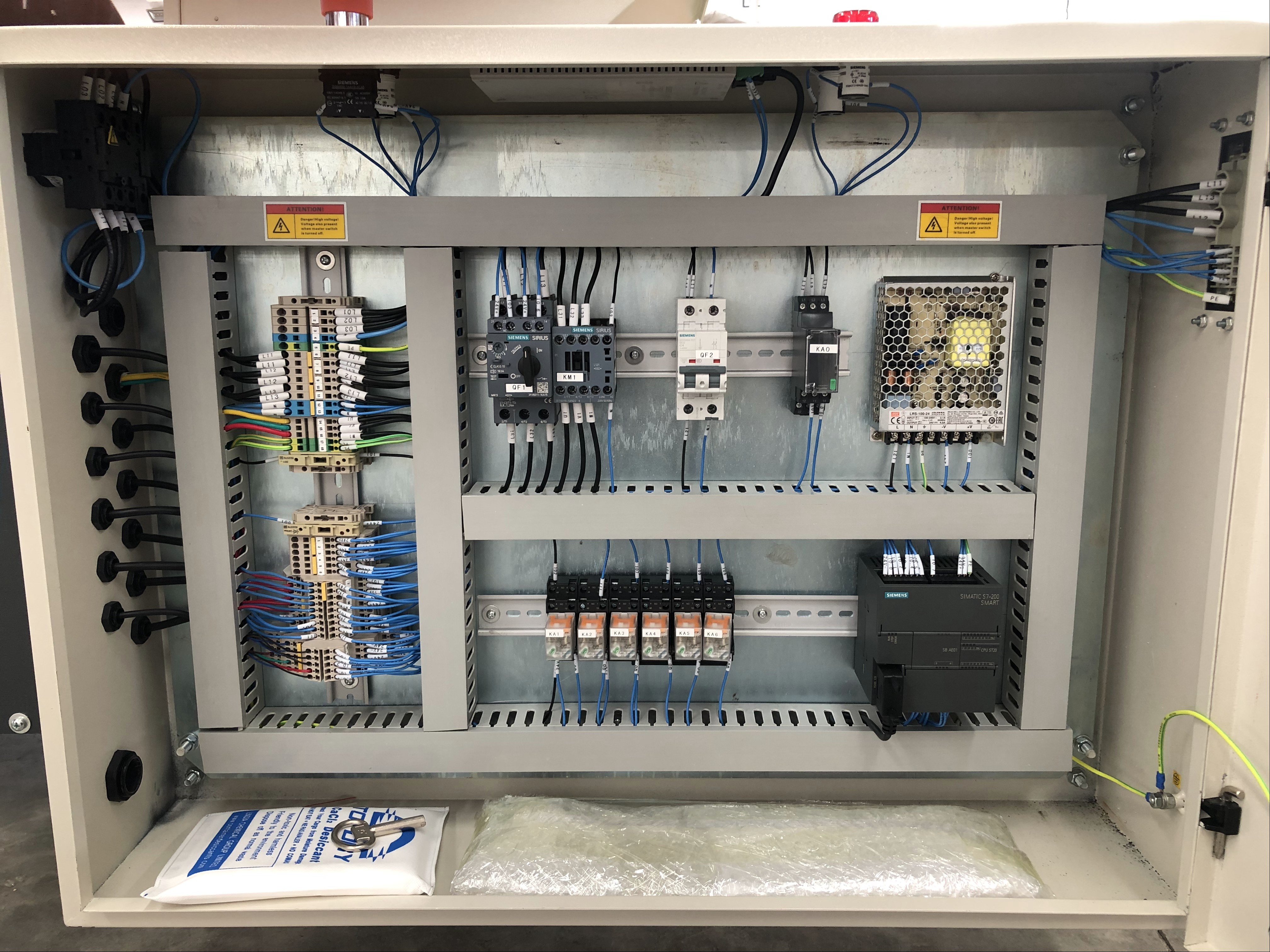

Intelligent PLC control system

The PLC electrical control system and industrial control configuration software are adopted as the core control concept. Through the centralized monitoring and management of electrical equipment, as well as the implementation of logical interlocking and protection control of related equipment, the safe, stable and efficient operation of the whole system is ensured, and the automatic control of equipment, starting, stopping, reversing and overload automatic reversing control functions are realized. The production can also be coordinated according to the equipment on the customer's site. At the same time, Through the detection of the material level and power of the crushing chamber, judge the current load of the crusher, optimize and adjust the control workload, so that the side is close to full load and operates under a better ore feeding state.

Решения для защиты информации с высоким уровнем безопасности на протяжении более 25 лет

Copyright © 2025 Zhejiang Supu Technology Co.,Ltd Support By BEE Cloud